Co-Ax is a highly versatile coaxially-designed process valve that can operate with almost all gaseous, liquid, gelatinous, contaminated, pasty, highly viscous or aggressive media, including vacuum. Its unique design means greater durability, repeatability, precision and performance. Take a look and see why!

Co-Ax was founded outside of Stuttgart, Germany in 1960 and was the originator of the coaxial-designed process valve. In 1997, Co-Ax opened up its North American facility near Philadelphia, Pennsylvania and today has operations and support around the world.

WHAT IS A CO-AX VALVE?

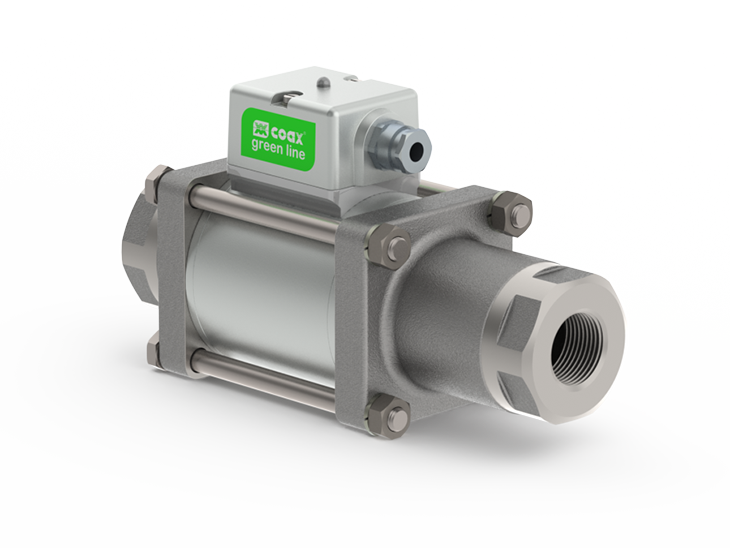

Co-Ax valves incorporate two elements, one inside the other. The external element or valve housing including the valve seat, is stationary. In order to shift the valve, the internal element or control tube is actuated, either by electrical power (direct-acting) or air (externally-controlled).

This co-linear design is what gives rise to the term coaxial valve. The external housing may have two or more inlets and outlets. The internal control element or control tube moves open or closed between the inlets and outlets and seats against an obturator style self-compensating seat.

Co-ax valves are pressure-balanced. Internal piloting is not required for valve operation.

WHEN SHOULD YOU CONSIDER USING A CO-AX VALVE?

- Ball, gate, globe or butterfly valves are too slow

- External leakage exists caused by stem seal leaks

- Internal leakage exists caused by seat wear or contamination

- Abrasive service requires constant maintenance and replacement

- High viscosity or non-lubricating fluids cause valves to stick and require excessive air pressure to operate

- High pressure gas service that demands “bubble-tight” shut-off

- Vacuum valves leak and/or cannot handle positive pressure for effective backfilling

- Space constraints for installation

- Application and media challenges when other valves fail…

- Water and coolant

- Fuels and gas filling

- Chemicals

- Power generation

- Plastics

- Contaminated media

- Food and beverages

- Paint applications

- Compressed air

- Inks and printing

- Recycling

- Slurries

A SUMMARY OF PRIMARY FEATURES AND BENEFITS:

- Pressure Balanced: The Co-Ax valve is always pressure-balanced because there is no system pressure working against the control element.

- Bi-Directional Flow: Because the control tube is a hollow cylinder, flow can be bi-directional. No dynamic seals to leak.

- Contaminated Media: Since Co-Ax valves don’t rely on any internal piloting, they are more contaminant tolerant for the toughest applications.

- Back Pressure Tight: In the de-energized state, the force of the valve spring causes the control tube to be positioned against the valve seat so that it is back pressure tight for positive shut-off.

- Fast Actuation: The unique pressure balanced design provides predictable positive shut-off, high cycle life and actuation speeds as fast as 30 milliseconds. This translates into greater durability, repeatability, precision and performance.

- Compact Design: Co-Ax valves do not require an external piggy-backed actuator to open and close. All of the valves components are engineered around the axis of the flow channel, keeping a compact profile. Installation possible in any orientation.