Challenge: Hydraulic & Pneumatic Cylinder Production Testing

Location: Wisconsin/Illinois

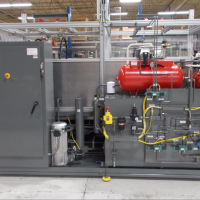

A major manufacturer of pneumatic and hydraulic cylinders called upon Flodraulic’s RHM Division to build a new production manufacturing test stand.

Through a co-operative engineering effort, RHM designed a turnkey test system capable testing all of their standard cylinders.

An integral 5,000psi hydraulic system and on-board air compressor provide the oil and air to operate the cylinders. Operational control circuitry is complemented by features such as safety interlocks for the operator gates, comprehensive system diagnostics, user-friendly control console and read-outs, quick roll-on/roll-off conveyor and cylinder coupling quick disconnects to speed up test time.

The electrical panel designed and built by RHM features Eaton’s Smartwire-DT intelligent machine wiring solution that reduces panel and machine wiring complexity by consolidating complex circuit wiring into a single ribbon cable.

The data acquisition system to capture and record cylinder test results was programmed and provided by Flodraulic’s UEP Panel Division partnership.

This production test system and another of a similar design have been provided to two leading fluid power industry cylinder manufacturers.

Suppliers

Experts in fluid power, electrical and mechanical technologies.